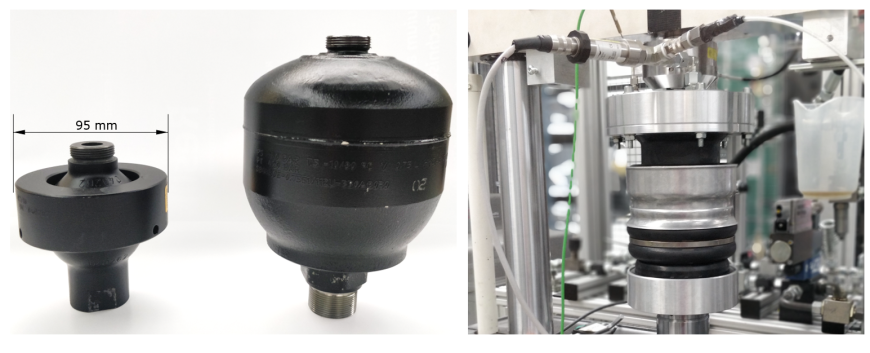

Gas accumulators are used in many technical systems to store energy. In mobile applications, these are used in suspension systems in the form of air springs and hydraulic accumulators.

The aim of this new transfer project is to increase the energy density of gas accumulators in dynamic applications. This can save weight and packaging, both very valuable properties in mobile applications.

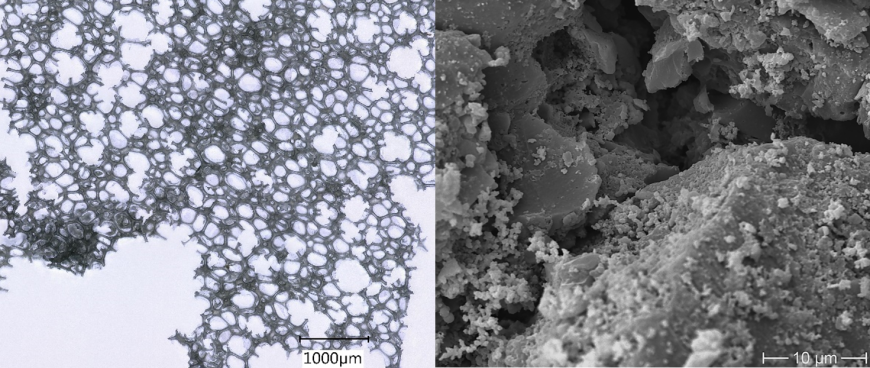

For implementation, two effects are used for this purpose, which act within the storage unit in a gas-solid system: (i) mass adsorption and (ii) heat absorption.

In this project, the experimental and analytical results from project C9 and C4 from the third funding period will be transferred to industry. The two industrial partners for this project are Vibracoustic, market leader in the field of passenger car air springs and Hydac, a company covering all needs in hydraulics.

The aim is to find and test an optimum material for both air springs and hydraulic accumulators that combines the two effects of mass adsorption and heat absorption. This can be done using models and optimization methods already developed for heat transfer in dynamic applications and mass adsorption.

| Photo | Name | Contact |

|---|---|---|

| Spokesperson | ||

| Prof. Dr.-Ing. Peter Pelz | peter.pelz@tu-... +49 6151 16-27100 |