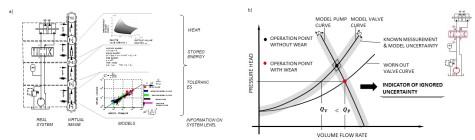

The detection of the system state will be realized by the synthesis of axiomatic and dimensional analytical model descriptions of the components with recorded measurement sizes. The targeted redundant determination of system sizes leads to data induced conflicts. The resolution of these conflicts either leads to greater confidence in the model-based specific sizes or register the detection of system changes. Using model adaptation the soft sensor network is able to respond to changes in the system behavior, for example by wear.

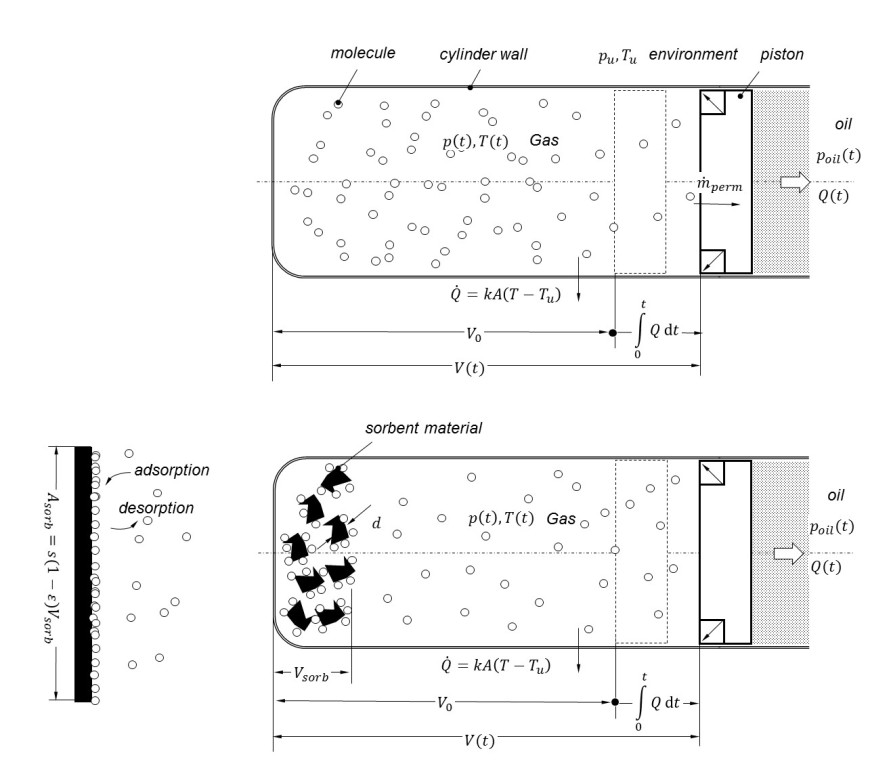

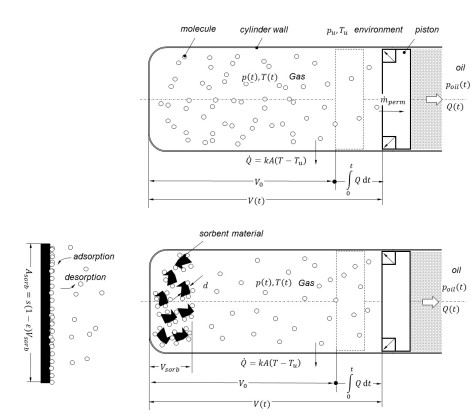

Beside the research on soft sensor networks another focus is on the technological development of pressure accumulators with sorbent material.

Accumulators play a major role in hydraulic systems. They fulfill essential functions, e.g., the storage of energy, the compensation of leakage or the absorption of pressure pulsations. Used as an energy storage in hydraulic drive systems, accumulators serve to cover peak loads and enable energy recuperation. On the one hand, this leads to energy savings and, thus, to higher system efficiencies, on the other hand, they allow the downsizing of hydraulic transmission systems. While the energy efficiency of accumulators was the object of numerous scientific studies, there is still potential of optimization concerning their reduction of size and weight. For this reason, a new accumulator will be developed, integrating sorbent material into the gas cushion. Sorbent material is characterized by its high porosity and, consequently, large surface. Activated carbon is a well-known example of sorbent material. It allows adsorption and desorption processes, i.e., gas molecules are accumulated on or dissolved from the sorbent surface due to Van-der-Waals forces. In this way, the sorbent material serves as another gas storage next to the gas cushion and motivates the usage of sorbent materials towards the reduction of weight and size of accumulators.

Subproject Managers

| Photo | Name |

|---|---|

| Prof. Dr.-Ing. Peter Pelz |